Countries Lead: Rapid Response & Repair

When a vaccine refrigerator fails in rural Rwanda, it’s not just a technical issue; it’s a race against time to get it fixed. With only one or two biomedical technicians per district, losing a single refrigerator can put thousands of vaccine doses at risk before help arrives.

Immunization systems require significant infrastructure investment, but countries with under-resourced health systems struggle to keep critical equipment operational over time. To help solve this problem, Nexleaf created ColdTrace, an end-to-end solution that transforms real-time performance data from vaccine cold chain equipment (CCE) into actionable insights. ColdTrace devices collect and mobilize continuous data on an interoperable platform, sending alerts when CCE breaks down or needs preventive maintenance.

However, data doesn’t fix fridges. People do.

That insight is at the core of Rapid Response & Repair (R3), an initiative Nexleaf launched in partnership with Gavi to activate the human side of digital transformation.

Rapid Response & Repair (R3) is built on a simple principle: countries are not simply the end users of digital tools—they are co-designers of them. Nexleaf partners with Ministries of Health to design and implement highly customized, concrete action plans to maximize the value of cold chain data for the health workers responsible for CCE management. By working directly with Ministries of Health from Day One, R3 ensures that country priorities guide both how data is used and how digital platforms evolve to meet emerging use cases.

Rwanda’s Unique Path to a Digitally Transformed Vaccine Cold Chain

In Rwanda, Ministry of Health leaders, health workers, Nexleafers, and our local implementing partners got to work on R3 in 2025. During the first R3 workshop, Ministry leaders and frontline technicians identified priority challenges that were undermining effective CCE management across the country.

Category 1: Human resources gaps

- Overburdened Staff: Only 1 or 2 biomedical engineers (BioMeds), the frontline health workers responsible for keeping medical equipment online, are assigned per district. Nationwide, approximately 46 BioMeds are responsible for managing more than 1,000 vaccine refrigerators, in addition to all other hospital equipment.

- Underutilized Staff: Health center vaccination nurses, who could serve as the first line of repair for minor fixes, had not been trained or empowered to troubleshoot or perform basic maintenance tasks.

- Undertrained Personnel: Staff capacity-building was inefficient and often ineffective due to a lack of hands-on, practical training and outdated training methods.

- High Turnover: Frequent staff turnover created knowledge gaps and maintenance delays.

These workforce constraints meant that even when cold chain data revealed a problem, the system often lacked the capacity to respond quickly.

Category 2: Lack of a centralized national equipment inventory & tracking

Rwanda lacked a digital dataset describing the location, make, and model of its fleet of vaccine refrigerators. Without this visibility, it was difficult to plan preventive maintenance, track performance, or procure spare parts efficiently. BioMeds lacked a fast and reliable mechanism to source the components needed to complete repairs.

Co-Designing Solutions with the Ministry of Health

Guided by these Ministry-identified priorities, the R3 partners designed two complementary solutions:

- Launch Learning & Enablement to train and empower a broader range of healthcare workers to support basic CCE maintenance and troubleshooting.

- Implement QR codes within the ColdTrace dashboard to create a national CCE inventory that integrates seamlessly with maintenance tracking for each piece of equipment.

Learning & Enablement for Vaccine Cold Chain Maintenance & Repair

Guided by priorities identified by the Ministry of Health, Rwanda’s Learning & Enablement program expands the country’s capacity to maintain vaccine cold chain equipment by empowering more health workers to perform routine maintenance while strengthening advanced skills among BioMeds.

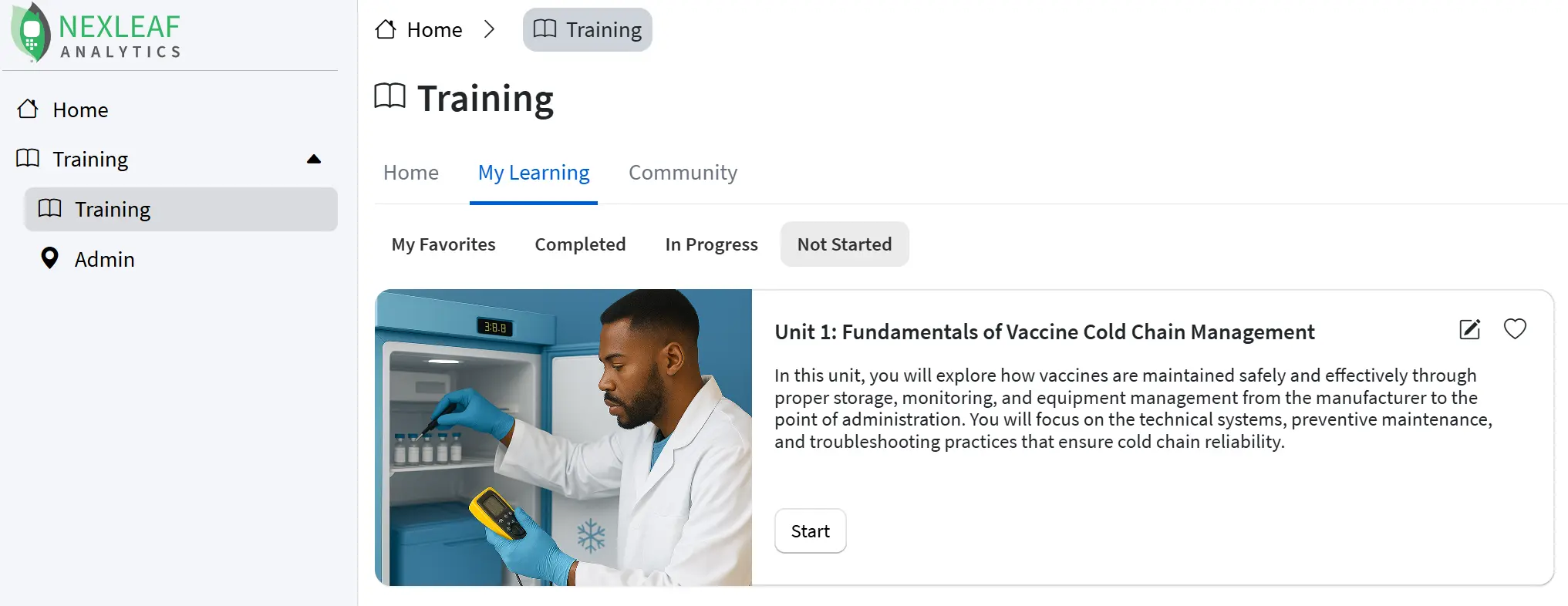

Learning & Enablement equips frontline health workers with on-demand, practical maintenance skills through a combination of digital learning and hands-on practice. The digital learning platform provides continuous learning for workers at all levels of the health system – not just BioMeds, but vaccination nurses as well. With multiple Vaccine Handlers and nurses on staff at every facility, empowering local personnel to troubleshoot and maintain fridges increases health system capacity, protects vaccines, and extends equipment lifespan.

“The problem we had in CCE, there always was a delay in the maintenance and repair when needed,” explained Aimee Pacifique Mukunzenkase, a BioMed at Nyarugenge district hospital. “But now that we are collaborating with the vaccinators from health centers, they are able to do certain things, and it helps us a lot.”

Maniraguha Daniel, a nurse in charge of vaccination at Rugarama Health Center, learned basic equipment maintenance techniques to prevent larger problems. “The cleaning part, to remove the dust and water, so that the refrigerator doesn’t encounter a problem we can’t solve by ourselves.”

“Before we were scared to touch anything related to electronics,” Daniel explained. “Now, easy things will be solved by ourselves. They [the BioMeds] have a lot of work, so we’ll call them only when necessary.”

Learning & Enablement also optimizes limited training resources through blended learning, which combines remote and in-person training. Health workers complete the first round of coursework via the ColdTrace platform, where lessons remain available for refresher training or onboarding new staff as needed.

Digital learning is followed by in-person practical sessions that reinforce online coursework and provide hands-on experience in fridge maintenance and repair.

“The courses were well prepared, online courses too. The content was comprehensive. The e-learning gave us time to read by ourselves. And we had time to do the practice too, face to face,” explained Mukunzenkase.

In addition to expanding access to training materials, the online coursework reduces in-person training, significantly lowering costs for the Ministry of Health while maintaining quality.

QR Codes: Adding a Feature to Nexleaf’s Platform for Innovative Equipment Management

During the R3 workshops, Ministry of Health representatives emphasized the need for a simpler way to track individual refrigerators and build out a digital inventory of Rwanda’s equipment. QR codes were identified as the most efficient and cost-effective solution. Rwanda’s EPI Manager Hassan Sibomana was instrumental in making the case for this innovation.

Like all software developers, Nexleaf must carefully prioritize feature development, and not every request can be implemented. In this case, however, Rwanda’s request for QR-code-enabled asset tracking addressed a critical national need while also offering clear value for other countries using ColdTrace.

“By working directly with frontline teams in Rwanda, we recognized how QR codes could streamline asset tracking and make maintenance workflows immediately accessible at the point of use,” says Susan Njenga, Head of Product at Nexleaf. “Their impact showed clear potential beyond Rwanda, across multiple countries.”

QR codes are familiar to health workers and ensure a unique identifier is associated with each piece of equipment. For the first time, Rwanda can link a specific refrigerator—at a specific facility—to its maintenance history and future needs, creating a feedback loop between frontline action and national decision-making.

Nexleaf and the Ministry are now working together to ensure that all of Rwanda’s vaccine fridges have unique QR codes affixed to them, and that each piece of equipment is associated with its proper profile in the ColdTrace dashboard.

Bringing It All Together

Beginning in November 2025, 40 Essential Programme on Immunization (EPI) Supervisors and 94 BioMeds from 34 district hospitals and 7 medicalized health centers – covering a catchment area of 376 of 516 health centers across the country – were invited to take the CCE Management online course. Within 3 weeks, 85% of EPI Supervisors and 67% of BioMeds completed the online course.

40 EPI Supervisors and 43 BioMeds were then invited to a 4-day in-person practical training session. Participants were divided into three groups, with trainers rotating between groups to provide hands-on instruction.

As part of this effort, Nexleaf’s Rwanda Country Manager, Moses Kasigazi, distributed 800 QR codes to district biomedical technicians and supported their implementation through instructional videos. These QR codes are being affixed during routine preventive maintenance visits—without incurring any additional operational costs—while enabling maintenance data to flow from facilities to the national level in real time. To date, BioMeds have placed 570 QR codes on vaccine refrigerators in their catchment areas, logging preventive maintenance activities that are now visible to national decision-makers.

The next phase extends this country-led approach even further. Health center managers and vaccination nurses across Rwanda are now participating in online CCE management training, with practical sessions planned at district hospitals.

Rwanda’s experience demonstrates what becomes possible when Ministries of Health lead digital transformation efforts—defining priorities, shaping tools, and strengthening systems from the ground up. Through R3, Nexleaf continues to partner with governments not just to deploy technology, but also to co-develop the capabilities needed to keep lifesaving equipment working today and for the long term.